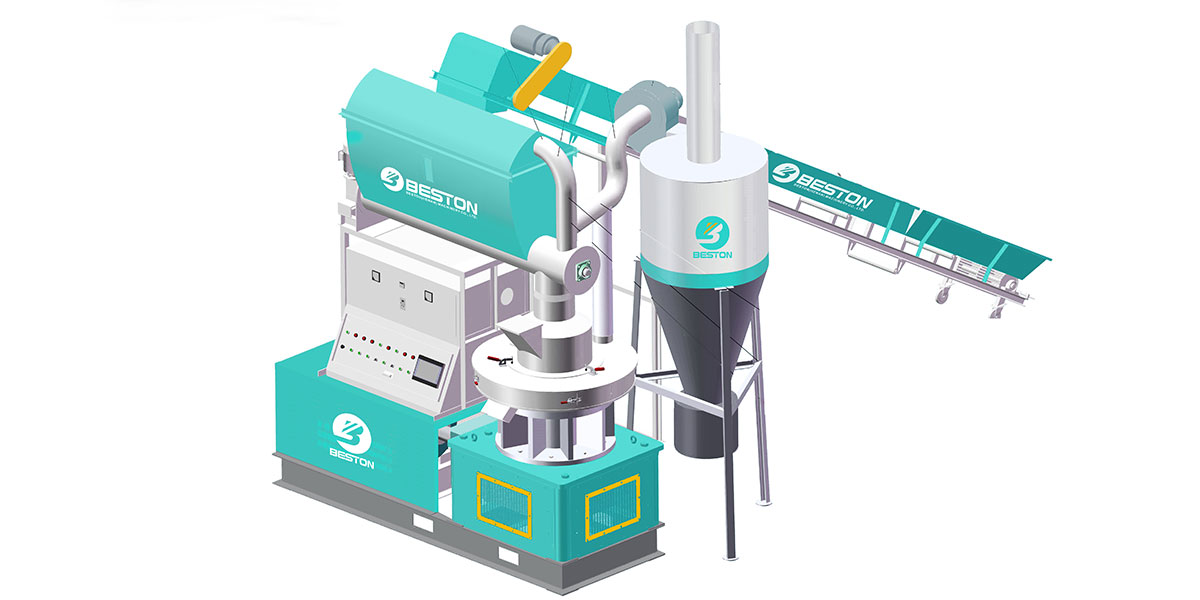

A sawdust pellet machine is a type of biomass-based energy equipment, which uses sawdust as the raw material. It is a good option for biomass-based power plants because of the advantages it provides. In addition to energy production, this sawdust pellet machine can also produce fuels and binders. The first step in converting sawdust into energy-efficient fuel is screening out the large pieces of wood and other undesirable materials. Then, the sawdust is sent to a roller dryer to be dried to the desired moisture level. A cyclone separator is used to separate the pellets from the moisture.

Sawdust Pellet Machine

Once the sawdust pellets are screened, they are transported to a storage silo. The pellets are then packaged in bags of 12, 15, or 20 kg. The packaging is usually plastic-wrapped for protection against moisture, and smaller bags are better for domestic use. The small-sized bags also reduce abrasion during transport. When using a sawdust pellet manufacturing machine, make sure the blades are positioned at the same distance from the flat die.

Once the pellets are processed and screened, they are packaged. For domestic use, a pellet machine that makes about two tons of sawdust per hour is a good choice. The smaller bags are ideal for home users and can be transported to storage silos without having to be weighed. You can also choose between bags of 12 kg, fifteen kilogram, or 20 kilograms. If you are selling your sawdust pellets, you can opt for large bulks, but this is not recommended for your business.

Another way to make sawdust pellets is to store the raw material in a warehouse. A warehouse with five to six tons of sawdust is sufficient for a 15-day production. For export, the pellets are packaged in bulk or in one-tone bags. The bags are wrapped in plastic to keep moisture and abrasion out. When packing your sawdust pellets, small bags are better than large bulks. More information on biomass pellet making machine here.

The sawdust pellet machine is an excellent choice for green-fuel production. Apart from producing green-fuel pellets, it can also be used for coffee seeds and palm kernel shell fiber. The main advantage of sawdust pellets is that they are highly resistant to moisture and are environmentally friendly. The production of biodiesel is an extremely profitable business. When installed properly, a wood pellet making machine for sale will produce a consistent amount of biomass fuel.

As you can see a sawdust pellet Machine can be an indispensable part of your daily operations. In fact, it is one of the best ways to add to the growth of your business. If you have any questions about the purchase of a sawdust pellet machine, please feel free to reach out to us.