In the realm of sustainable waste management and resource recovery, the pyrolysis plant stands as a beacon of innovation, offering a nuanced solution to the conundrum of plastic waste. This article delves into a meticulous examination of the cost-benefit dynamics inherent in the deployment of pyrolysis plants, exploring their multifaceted implications on both economic and environmental fronts.

Pyrolysis Fundamentals

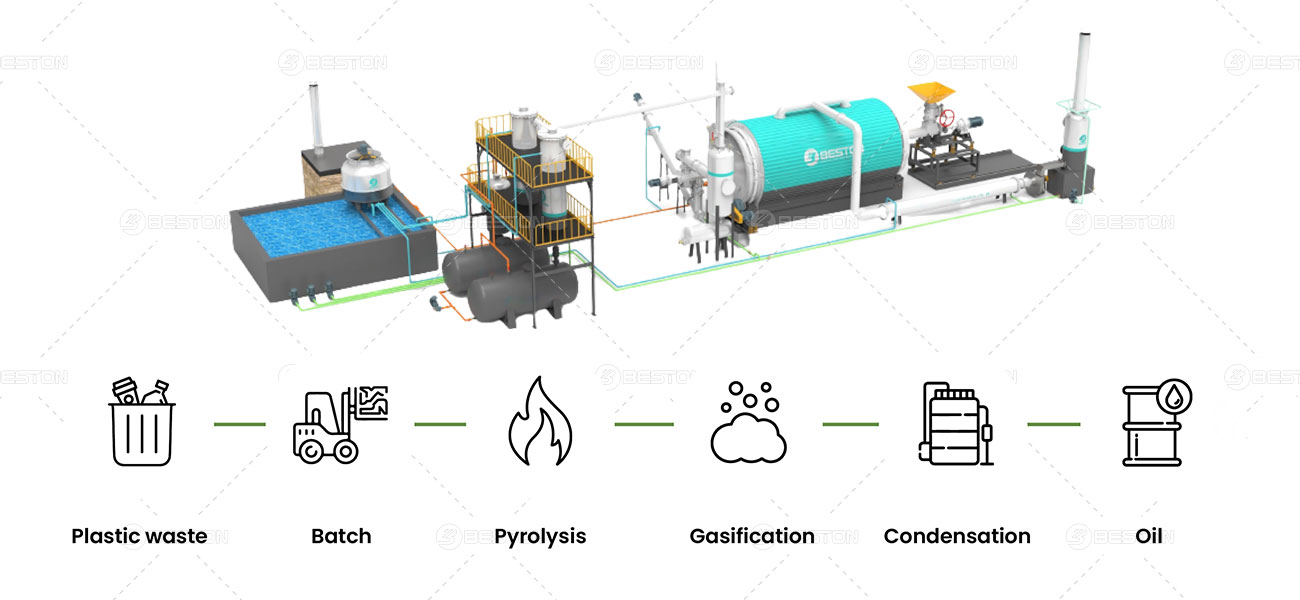

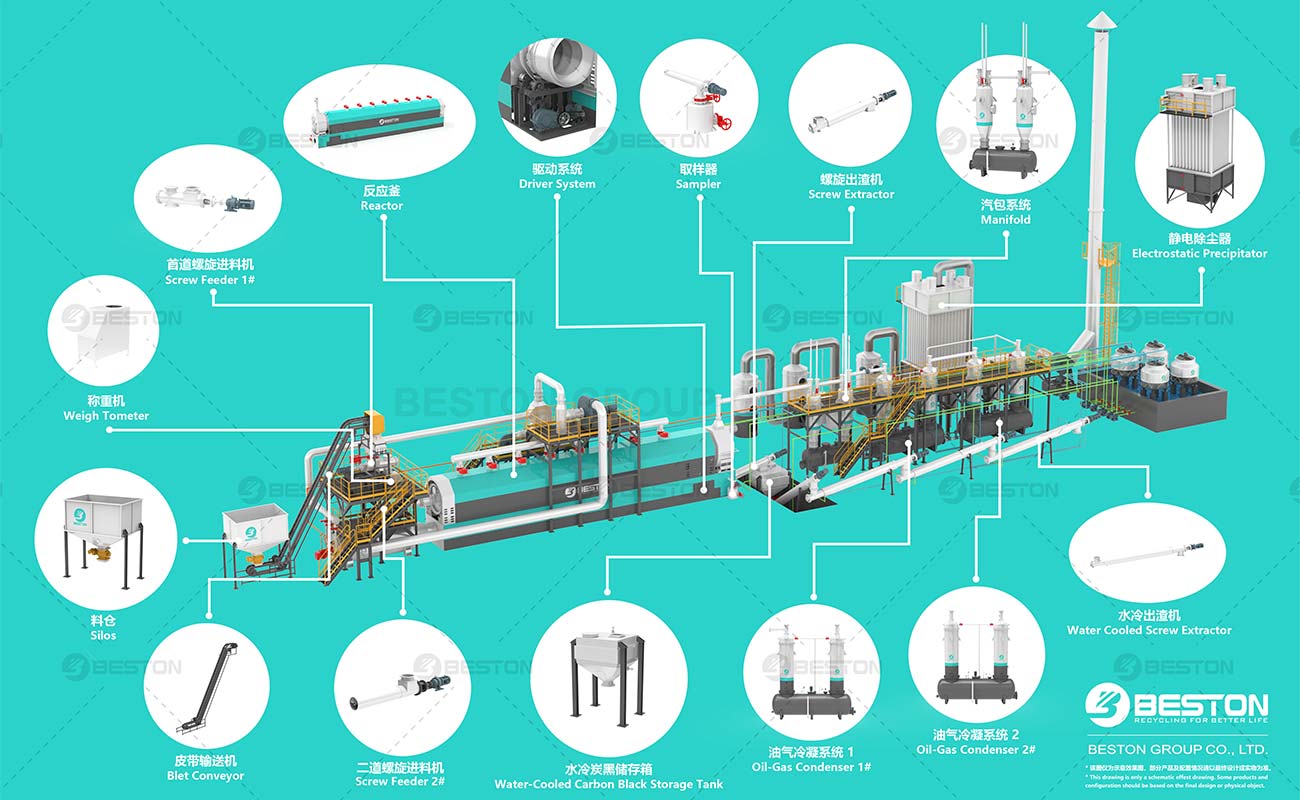

Pyrolysis, an intricate thermochemical process, emerges as the linchpin in this narrative. It involves subjecting waste plastics to elevated temperatures in an oxygen-deprived environment, catalyzing the conversion of complex polymers into more manageable byproducts. The heart of this operation is the pyrolysis plant, a sophisticated facility designed to orchestrate this intricate ballet of heat, pressure, and molecular transformation.

Economic Vantage Point

From an economic standpoint, the viability of pyrolysis plant hinges on their capacity to yield valuable outputs from seemingly unyielding waste. The primary economic benefits encompass the production of marketable commodities, with the endearing prospect of converting discarded plastics into liquid fuels, gases, and char.

In scrutinizing the economic merits, it becomes apparent that the initial investment in establishing a pyrolysis plant is a pivotal consideration. The procurement of cutting-edge pyrolysis reactors, capable of sustaining the requisite high temperatures, constitutes a significant fraction of the capital expenditure. Furthermore, auxiliary systems for gas and liquid collection, condensation, and product separation contribute to the comprehensive fiscal panorama.

Despite the initial financial outlay, the long-term dividends of operating a pyrolysis plant are compelling. The produced liquid fuels, colloquially known as pyrolysis oil or bio-oil, present a lucrative avenue for revenue generation. These fuels, comparable to traditional fossil counterparts, can be utilized in diverse industrial applications, effectively transforming waste into a valuable commodity.

Environmental Imperatives

The environmental benefits interwoven with batch/continuous pyrolysis plant operations transcend the reduction of landfill burden. By diverting plastics from traditional disposal methods, these plants contribute substantially to mitigating environmental degradation associated with conventional plastic disposal. The process itself, devoid of oxygen, circumvents the release of harmful gases commonly associated with combustion.

Moreover, the solid residue, or char, generated during pyrolysis, assumes a role in carbon sequestration. With applications in agriculture as a soil amendment, char holds promise in fostering sustainable land use practices, thereby aligning with broader ecological objectives.

Keywords in Focus

Let’s dissect the keywords to offer a granular exploration of their significance within the context of pyrolysis plants:

- Tyre/Plastic/Oil Sludge Pyrolysis Plant: The nucleus of this discourse, the pyrolysis plant, embodies the convergence of engineering ingenuity and environmental responsibility. Its role as a transformative hub for waste plastics accentuates its prominence in the pursuit of sustainable waste management.

- Economic Viability: At the nexus of industry and ecology, the economic viability of pyrolysis plants is contingent on a judicious balance between initial capital investments and long-term returns. The allure of converting waste into marketable commodities underscores the economic rationale behind these ventures.

- Pyrolysis Reactors: The crux of the pyrolysis process, these reactors epitomize the technological backbone of pyrolysis plants. Engineered to withstand extreme temperatures, these reactors facilitate the controlled breakdown of plastics into valuable byproducts.

- Pyrolysis Oil/Bio-Oil: The liquid elixir arising from pyrolysis, often referred to as pyrolysis oil or bio-oil, represents the tangible fruits of this transformative process. As a versatile fuel source, its economic potential amplifies the attractiveness of pyrolysis plants.

- Char: Beyond its mere designation as a solid residue, char encapsulates the environmental conscientiousness of pyrolysis plants. With applications in carbon sequestration and soil enhancement, char crystallizes the symbiotic relationship between waste management and ecological stewardship.

The Landscape of Challenges

However, the landscape of oil sludge/tyre/plastic pyrolysis equipment deployment is not without its challenges. The need for efficient plastic sorting, the scalability of operations, and the continuous quest for enhanced economic efficiency linger as formidable hurdles. Addressing these challenges is imperative for the widespread adoption of pyrolysis as a mainstream waste management solution.