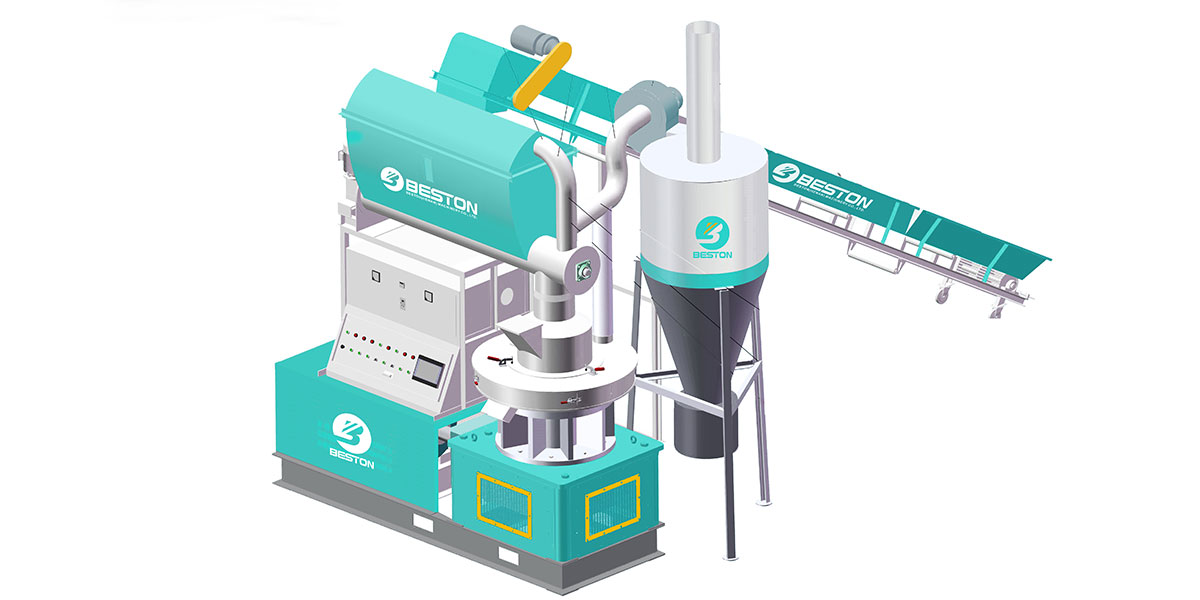

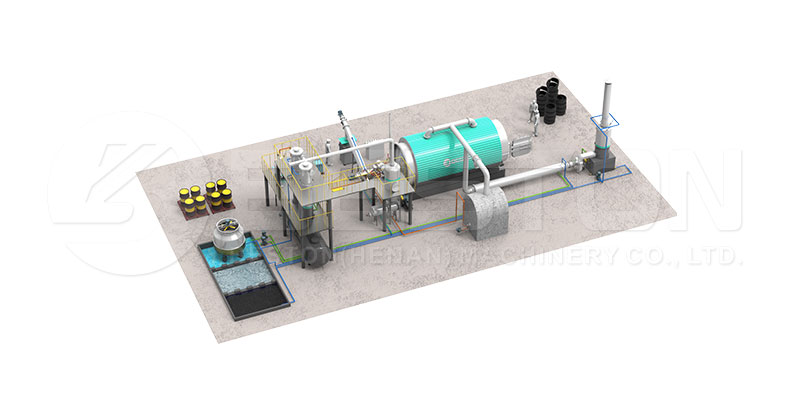

There is a new machine on the market that can turn any kind of biomass into biochar. This machine has the potential to revolutionize the way we produce biochar, and could help us meet our emissions targets. The biochar machine is a simple, modular design that can be easily scaled up or down to meet the needs of any farm or forest. It is powered by renewable energy, and produces no emissions. The machine is designed to be used with any kind of biomass, including wood chips, straw, and even manure.

What Does the Biochar Machine Do?

The biochar machine is a device that helps to create biochar, a type of charcoal that can be used as a soil amendment. The machine works by burning biomass, such as wood or crop waste, in a low-oxygen environment. This process creates a char that is rich in carbon and other nutrients. Biochar can be used to improve soil fertility and water retention, as well as to reduce greenhouse gas emissions. The machine is also designed to be portable, so it can be used in remote areas where other methods of char production are not available.

BST-10 Biochar Making Machine

What Makes the Biochar Machine Stand Out?

The biochar machine is different from other machines on the market because it produces a special type of charcoal that can be used as a soil amendment. This charcoal is made from biomass, such as wood or agricultural waste, and it is rich in carbon. When added to soil, biochar helps to improve fertility and water retention. It also reduces the need for chemical fertilizers, making it an environmentally friendly option. The charcoal making machine is specially designed to produce high-quality charcoal, and it is available in a variety of sizes to meet the needs of farmers and gardeners. If you are looking for an environmentally friendly way to improve your soil, the biochar machine is an excellent option.

How Can the Biochar Machine Help Us Meet Our Emissions Targets

The need to reduce our carbon emissions is urgent, and the biochar machine offers a promising solution. The machine produces charcoal from biomass, which can then be used as a soil amendment. Biochar has many benefits for the environment: it helps to improve soil fertility, increases water retention, and reduces greenhouse gas emissions. Moreover, the process of producing biochar is carbon-negative, meaning that it actually helps to remove carbon dioxide from the atmosphere. Given its many benefits, it’s no wonder that the biochar production equipment is gaining popularity as a tool for fighting climate change. As we work to meet our emissions targets, the biochar machine will play an essential role in helping us achieve our goal.

Biochar From Biochar Machine

Why It’s Worth Buying a Biochar Machine

The biochar machine is a powerful tool that can help to improve the soil quality in your garden. By breaking down organic matter into char, the machine provides a source of nutrients and helps to improve drainage and aeration. In addition, the small charcoal making machine helps to create a more ideal environment for beneficial microbes, making it an essential tool for any serious gardener. While the initial investment may be higher than other methods of soil improvement, the long-term benefits of the biochar machine make it well worth the price. With proper care and maintenance, the biochar machine will provide years of service, enabling you to generate a good return on your investment.