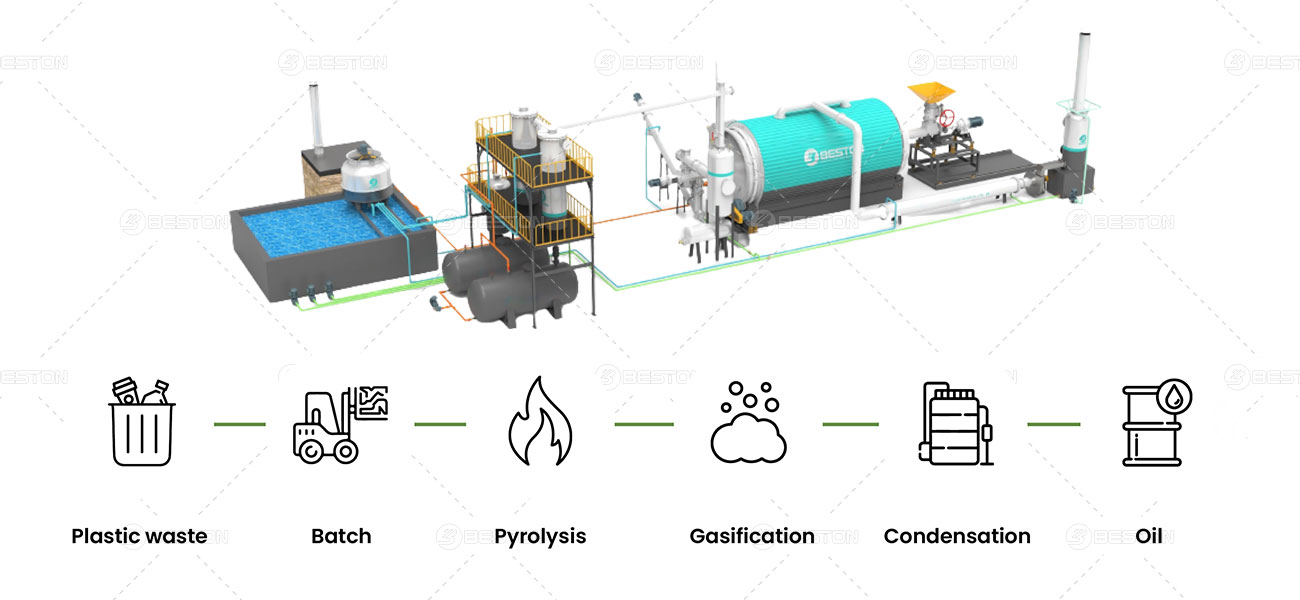

The quality of plastic input plays a crucial role in determining the efficiency and effectiveness of the pyrolysis process. Pyrolysis, a thermal decomposition of organic material in the absence of oxygen, is widely used to convert plastic waste into valuable products such as fuel oils, gases, and solid residues. However, the purity of the plastic waste significantly influences the outcome of the process. In this article, we will explore the impact of plastic purity on pyrolysis efficiency, focusing on how impurities in plastic waste affect the pyrolysis plant’s performance and product quality.

The Role of Plastic Purity in Pyrolysis

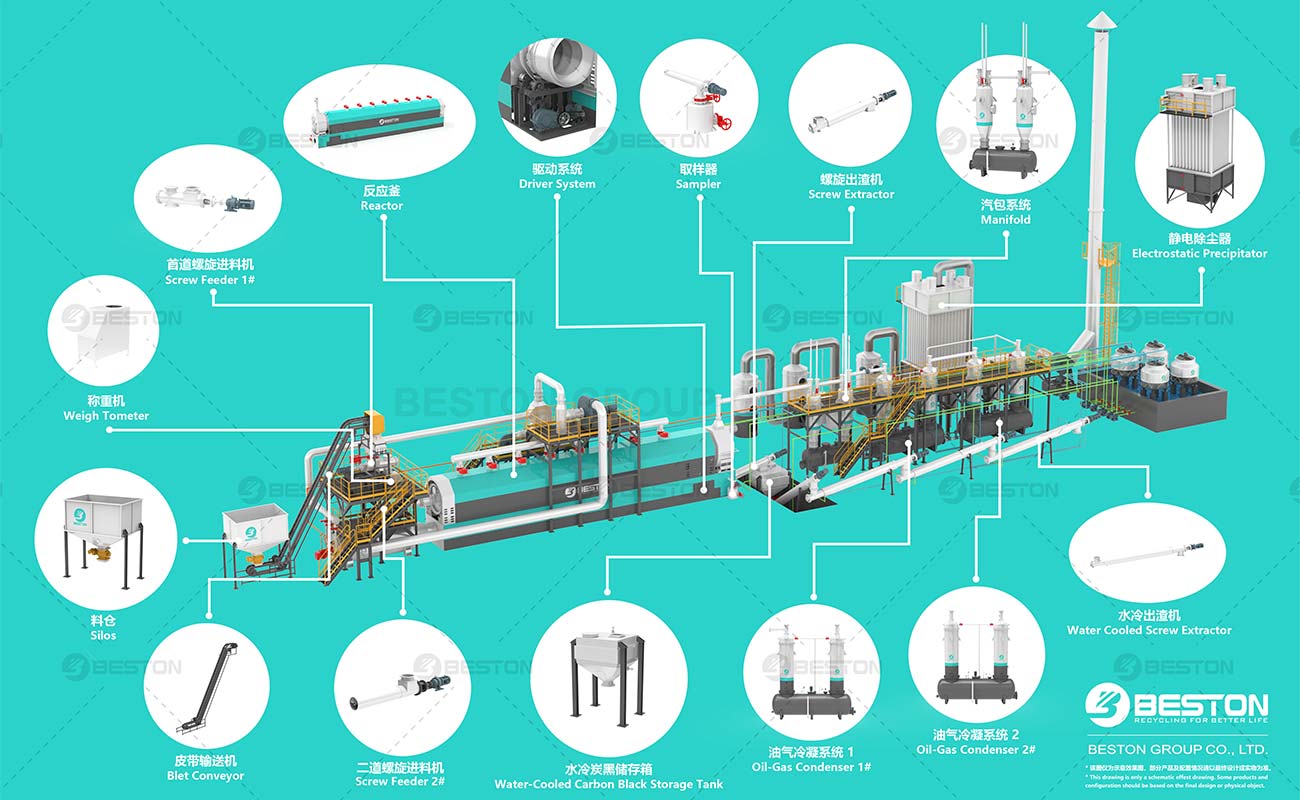

Plastic waste typically contains a mixture of different types of plastics, some of which may include contaminants such as metals, paper, or organic materials. The purity of the plastic feedstock can directly impact the efficiency of the plastic pyrolysis machine, influencing both the yield and quality of the products produced.

Plastics such as polyethylene (PE), polypropylene (PP), and polystyrene (PS) are more suitable for pyrolysis due to their chemical structure and lower melting points. On the other hand, plastics like polyvinyl chloride (PVC) can introduce unwanted chlorine during pyrolysis, which leads to the formation of corrosive gases and byproducts. Such impurities can decrease the overall efficiency of the pyrolysis process, requiring additional processing or expensive equipment to mitigate the negative effects.

Effect of Impurities on Product Yield and Quality

One of the most significant impacts of plastic impurity is on the yield and quality of the pyrolysis products. Clean plastic feedstocks tend to produce higher yields of high-quality pyrolysis oil and gases, as they undergo a more predictable decomposition process. These products can be further refined or used directly as industrial fuels or chemical feedstocks.

Contaminants, however, can lead to the production of lower-value byproducts, such as tar or solid residues. These impurities interfere with the cracking process, which is responsible for breaking down large polymer chains into smaller, more useful molecules. The presence of impurities can cause incomplete or inefficient pyrolysis, resulting in an excess of heavy hydrocarbons or char that is harder to utilize.

Additionally, contaminants such as metals or inorganic materials can damage the plastic into fuel machine. This can lead to increased maintenance costs and reduced operational efficiency over time. It is also possible for the contaminants to react with other chemicals in the process, creating harmful byproducts or creating operational safety hazards.

Optimizing Feedstock Quality for Improved Efficiency

To achieve optimal pyrolysis efficiency, it is crucial to ensure the plastic feedstock is as clean and pure as possible. Pre-treatment steps, such as sorting and cleaning the plastic waste, can significantly improve the quality of the feedstock and reduce the impact of impurities.

Sorting plastics by type is one of the most effective methods for improving purity. Automated sorting technologies, such as infrared spectroscopy or air classification, can be used to separate different plastic types and remove non-plastic contaminants. For instance, separating PVC from PE and PP plastics prevents the release of harmful chlorine during pyrolysis.

Another important step is to remove non-plastic contaminants such as metals, labels, and organic materials. This can be done through mechanical processes like shredding or washing, which reduce the impurity levels and improve the overall consistency of the plastic feedstock. The cleaner the feedstock, the better the performance of the pyrolysis reactor.

Economic Implications of Feedstock Purity

The economic performance of a plastic to oil plant is closely tied to the purity of the plastic feedstock. High levels of contaminants can lead to lower product yields, decreased product quality, and increased operational costs due to additional processing requirements and more frequent maintenance. In contrast, cleaner feedstocks result in more efficient pyrolysis, higher-quality products, and lower costs associated with maintenance and equipment replacement.

While sorting and cleaning plastic waste might increase initial investment costs, it can lead to better returns in the long run by improving the efficiency and profitability of the pyrolysis process. Furthermore, cleaner products are often more marketable, offering better opportunities for commercialization and increased revenue generation.

Conclusion: The Critical Role of Purity in Pyrolysis

The purity of plastic feedstock is a crucial factor in determining the success of a pyrolysis plant. Clean, well-sorted plastics yield higher-quality products and enhance operational efficiency, while contaminated feedstocks lead to lower yields and increased costs. As the demand for sustainable plastic waste management solutions grows, optimizing feedstock quality will become an essential practice for maximizing the economic and environmental benefits of pyrolysis technology.