Human societies are advancing and adapting slowly to our place on the planet by learning to manage our waste production and make the most from recycled materials. To this end, tire pyrolysis plant is being designed, manufactured and made available to a world in need.

In the following article you can learn more about this amazing innovation and how it can be applied to saving your world and countryside from the black rubbery menace.

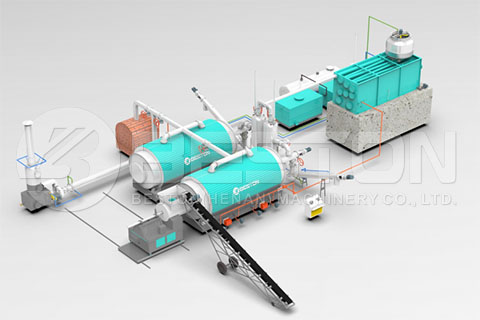

Waste Tyre Pyrolysis Plant

The Problem with Tyres

Tyres are being used and discarded faster than they can be effectively disposed of and the biggest problem is, they aren’t really disposable. Tyres will remain in a landfill, thrown in an empty field or tossed into the local river for many years while their valuable constituents are leached into the ground in toxins and poisons that harm ourselves and our world. Get pyrolysis plant cost estimate here.

For this reason, many landfills and regular garbage collection facilities will no longer accept tyres. If this hasn’t been applied to your local area, you can imagine it will soon as local legislators are made increasingly aware of the dangers of uncontrolled waste.

But, tucked away inside these rubbery loops is a variety of valuable materials and useful compounds that can be repurposed rather than left to add strain to an already unhealthy ecosystem. Using primitive technology but highly advanced machinery, the tyre pyrolysis machine offers solutions to a considerable problem with waste management.

The world discards as many as 300 million tyres in a single day meaning that a virtually inexhaustible supply of tyres are available for use. All that is needed is an intelligent plan to collect these tyres and use them in a more productive way. Through the process of pyrolysis these tyres can be transformed into their most valuable constituents and resold to various manufacturing or energy industries as the needs demand.

Pyrolysis can be translated to “transformed by fire” from the original Latin and presents an amazing way to obtain useful fuel and other materials from ordinary substances and compounds. This is done by burning the compounds without any oxygen present. Ancient agricultural civilizations would use pyrolysis to change organic fibers and even waste products into biochar used for fertilizing farmlands. More information on tyre recycling plant in Nigeria here.

Of course, the primitive methodologies of the ancients would be no good and produce way too much noxious gasses and released CO2 to be effective with tyres. To transform the tyre into something useful and practical requires sophisticated machinery.

Pyrolysis Plan To South Africa

The Pyrolysis Process in the Tyre Pyrolysis Machine

Inside the pyrolysis reactor, tyres will be burned at high temperatures but without the presence of oxygen to aid the fire. The results in a chemical transformation of the chemicals and materials in the tyre. The polymers in the rubber itself will be evaporated and these gasses can be collected and condensed in a condenser to produce biofuel. This “biofuel” has a high caloric value and can be applied as a suitable fuel to meet the impending energy crisis.

But, there’s more One the process of pyrolysis is complete, your waste tyres will be reduced to carbon black and scrap steel. Yes! There is steel within the reinforced walls of the tire. Both carbon black and this scrap steel also have extensive application in various industries.