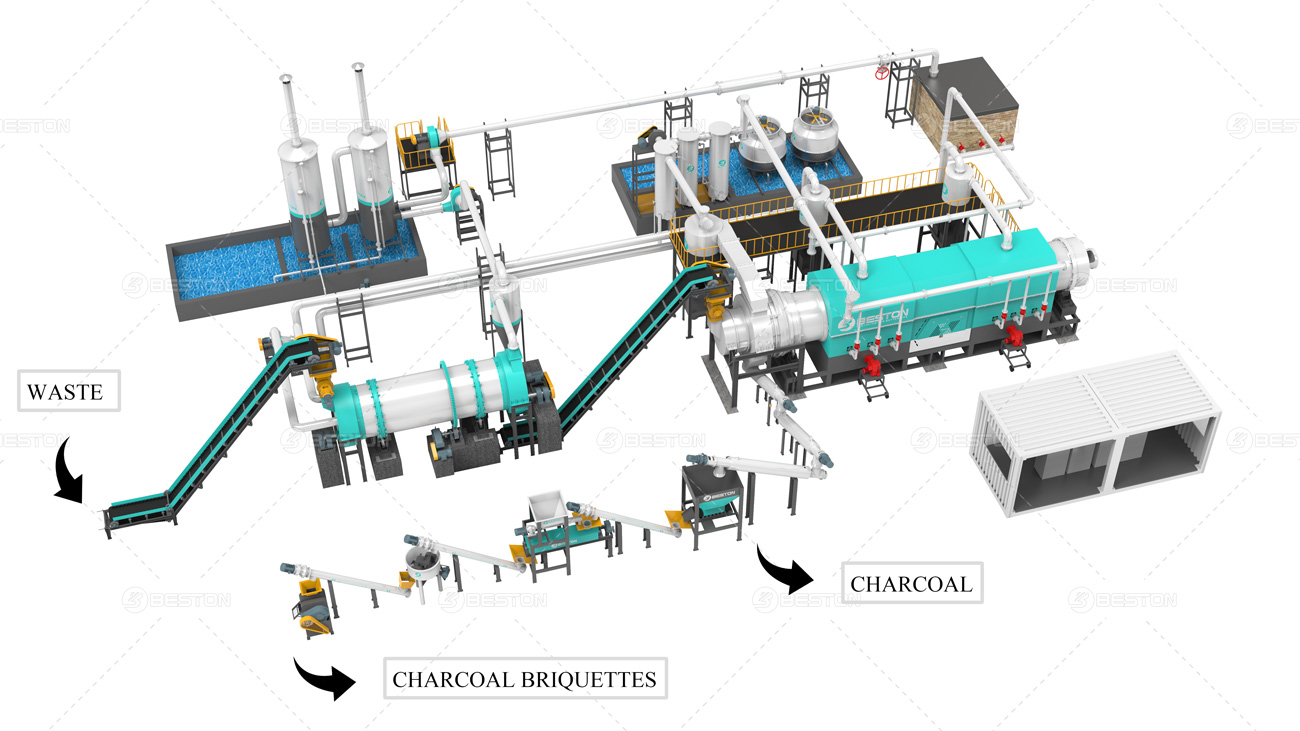

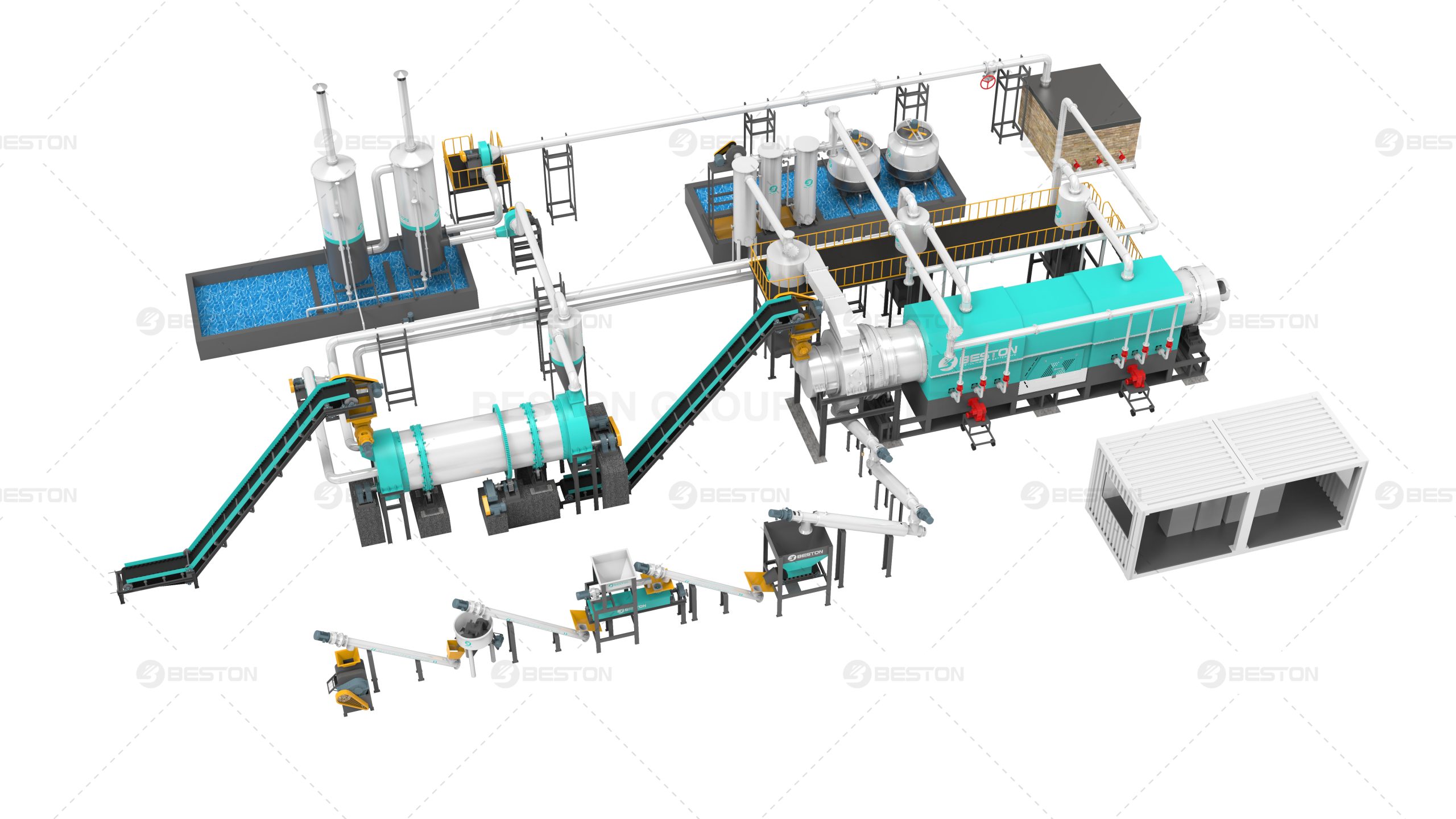

Biomass pyrolysis is a high-temperature process that decomposes organic material in the absence of oxygen, transforming it into valuable by-products such as bio-oil, syngas, and biochar. This process takes place in a biomass pyrolysis plant and occurs in distinct stages, each contributing to the transformation of raw biomass into these marketable products. Understanding these stages is crucial for optimizing the pyrolysis process and improving both efficiency and yield.

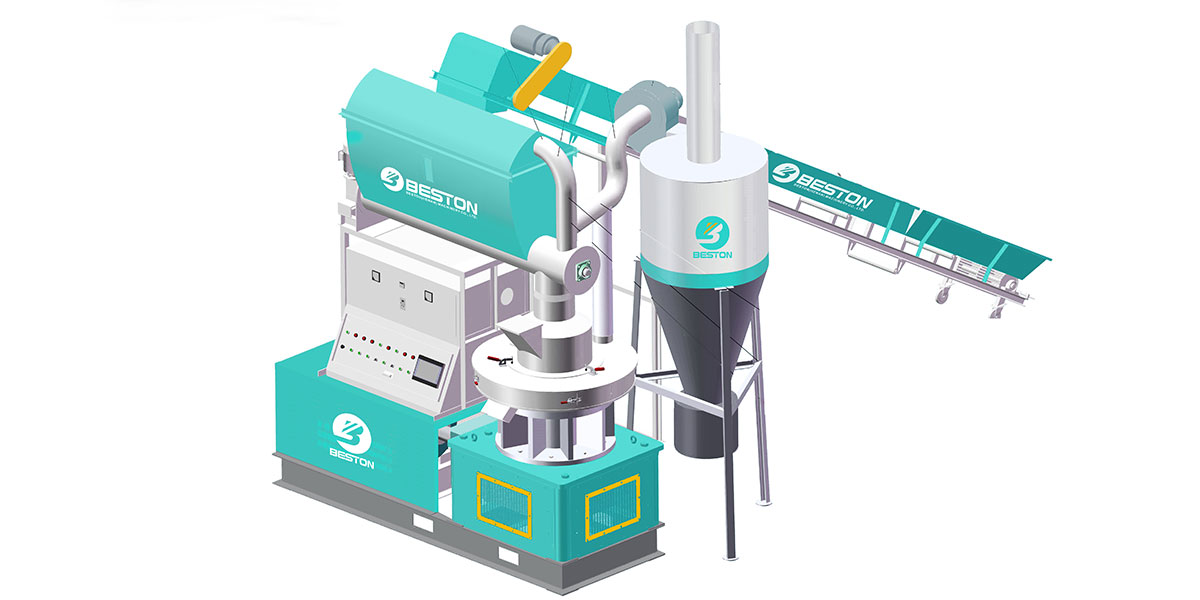

1. Drying of Biomass

The first stage in biochar production equipment is the drying of the feedstock. Biomass typically contains a significant amount of moisture, which must be reduced to ensure the efficiency of the pyrolysis process. In this stage, heat is applied to evaporate the moisture content, converting the biomass into a more energy-dense material that is better suited for thermal decomposition.

During drying, temperatures typically range from 100°C to 200°C. The rate of drying is highly dependent on the biomass’s moisture content and its structure. This stage is critical, as excess moisture can interfere with the pyrolysis reaction, leading to lower efficiency and incomplete decomposition.

2. Dehydration and Devolatilization

Following the drying process, the biomass enters the devolatilization stage, where the complex organic polymers in the feedstock begin to break down into simpler volatile compounds. This stage involves the pyrolysis of biomass at temperatures ranging from 200°C to 600°C.

During devolatilization, the chemical bonds of cellulose, hemicellulose, and lignin in the biomass are broken down, producing volatile gases such as methane, carbon dioxide, and other hydrocarbons. These volatile compounds contribute to the production of syngas, a gaseous by-product that can be used for energy generation to biomass pyrolysis plant for sale. The remaining solid material, known as char, is also formed during this phase.

This stage is characterized by rapid weight loss as volatile matter is released. The efficiency of devolatilization is heavily influenced by factors such as heating rate, temperature, and the physical properties of the biomass being processed. Proper control of these factors can lead to a higher yield of valuable by-products, such as bio-oil.

3. Char Formation and Carbonization

The third stage of biomass pyrolysis is char formation and carbonization. As the temperature rises further (typically above 400°C), the remaining solid residues undergo a process of carbonization. This is where the biomass material begins to transform into biochar—a carbon-rich material that can be used for various applications, including soil amendment and as a fuel.

During this stage, the volatile gases released in the previous step are condensed, leading to the formation of liquid bio-oil. The biochar produced at carbonization furnace has a high carbon content and low moisture, making it an excellent product for energy generation and carbon sequestration purposes.

The carbonization process is vital for maximizing the yield of biochar. The temperature and residence time in the reactor can significantly affect the quality and quantity of biochar produced. High temperatures result in a more carbon-dense product, whereas lower temperatures may leave more volatile material behind in the biochar.

4. Cooling and Condensation

Once the pyrolysis process is complete, the remaining gases and vapors are directed to a cooling and condensation system. In this stage, the volatile compounds, such as water vapor, light hydrocarbons, and tar, are cooled and condensed into bio-oil. This bio-oil is a valuable product that can be refined and used as a renewable energy source.

The cooling process involves passing the hot gases through a series of condensers where they lose heat, causing the volatile compounds to condense. The bio-oil can be collected and stored for further processing, such as refining to increase its energy density or to produce various chemical compounds.

Simultaneously, syngas, the gaseous by-product from the pyrolysis reaction, is typically captured and can be used to generate heat or electricity for the biomass pyrolysis plant. This helps reduce energy consumption and increases the overall energy efficiency of the system.

Want to get equipment equipped with the latest pyrolysis technology? Contact Beston Group.

5. Post-Pyrolysis Handling of By-products

After the cooling process, the final by-products of biomass pyrolysis—biochar, syngas, and bio-oil—are handled separately. The biochar is removed from the reactor, while the bio-oil and syngas are directed toward collection and storage. At this stage, it’s important to monitor the quality of the bio-oil and syngas to ensure that they meet industry standards and are suitable for further use.

Biochar can be used in a variety of applications, such as soil enhancement, carbon sequestration, and as a renewable energy source. The syngas, once cooled and purified, can be used for energy generation within the biomass pyrolysis plant or sold to external customers. Bio-oil, on the other hand, can be refined and sold as a substitute for conventional fossil fuels.