Egg tray machines are a fantastic way to automate the process of sorting and storing eggs from your chicken farm. These machines come in a wide range of sizes and designs, but most commonly, they fall into the category of manual, semi-automatic, and automatic. For a small operation with a limited budget and few customers, the manual egg tray machine offers fantastic value and can still deliver. However, larger facilities that have a sizable output, semi-automatic and automatic machines (máquina de bandeja/maple/cubeta de huevos de pulpa) help automate the process.

Machines meant for producing egg trays are also capable of creating other items, such as milk cartons or drink holders as well. In order to achieve these results, however, certain modifications have to take place.

Pricing Variations

The most affordable equipment is a manual egg tray machine (máquina formadora de bandeja/maple/cubetas de huevos) as it requires full manual operation in order to create the number of trays you require. A good middle class alternative to the most expensive and most affordable option is the semi-automatic machine that is able to carry out some work with programming. However, the most expensive equipment of all is fully computer run and programmable with an output of anywhere from 1,000- 7,500 trays per hour. This is a costly investment, but one well worth considering for a serious company.

Another aspect to consider when calculating your budget for an egg tray machine is the quality of the equipment parts. A high quality and efficient machine that is capable of producing a large number of trays requires a sizable investment.

What Kinds Of Trays Can I Produce?

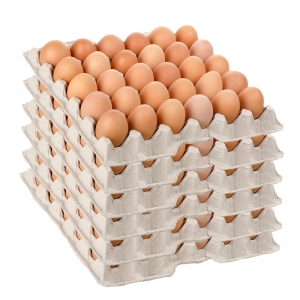

Though the idea of an egg tray may seem basic, there are plenty of options to choose from when purchasing manufacturing equipment. Trays are always square or rectangular based on the type of machine manufacturing them. The trays are able to help cradle the eggs in a protective position, but the right kind of equipment may also have the ability to manufacture egg boxes (máquina para fabricar cartón de huevos) for added safety.

Standard egg tray sizing is capable of holding three dozen or 36 eggs. However, this number is also subject to change and trays can be manufactured to house anywhere from 6 to 12 eggs apiece. Proper machinery is also responsible for ensuring that the trays or boxes produced on the line are hygienic and clean in order to protect the eggs.

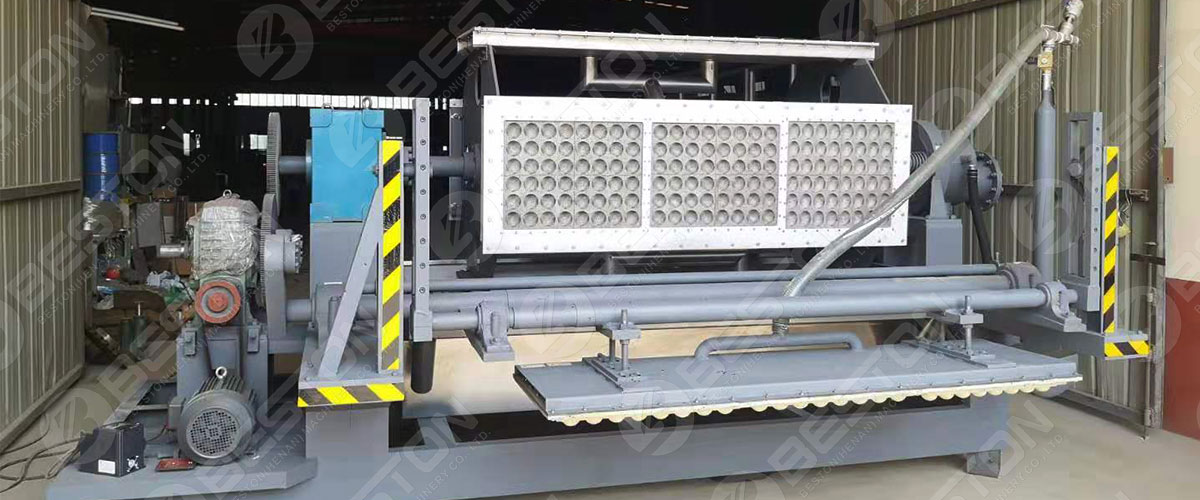

The 3 Parts Of An Egg Tray Machine

1. Pulping

The first part of the process is the pulping framework which contains a number of components such as pulpier, mash pump, refiner, blender, and control cabinet. The pulp can be manufactured from recycled paper as well to help a business remain eco-conscious.

2. The Drying Line

After the pulp is mashed and framed, it is formed and sent onto the drying line. Once the tray is properly dried, it moves to the next channel. This line can be powered by either bricks or a metal drying line.

3. The Packing Line

After the egg tray is dry, it is sent to the final stage of manufacturing which is the packing line.

An egg tray machine is an invaluable purchase for your company when needing to sort, display, and sell eggs. You can use recycled paper to create the pulp, and still retain an environmentally friendly approach to manufacturing, but it takes some due diligence to find the right equipment: https://www.bestongroup.com/es/.