In the dynamic landscape of waste management, technologies like waste pyrolysis have emerged as potential game-changers. This post aims to delve into the intricate world of waste pyrolysis, exploring its processes, potential benefits, and the ecological impact it leaves in its wake. As we navigate this path, we will critically analyze the environmental implications of waste pyrolysis and question whether it truly stands as a beacon of sustainability or if concerns linger beneath the surface. The suitable pyrolysis plant is the key.

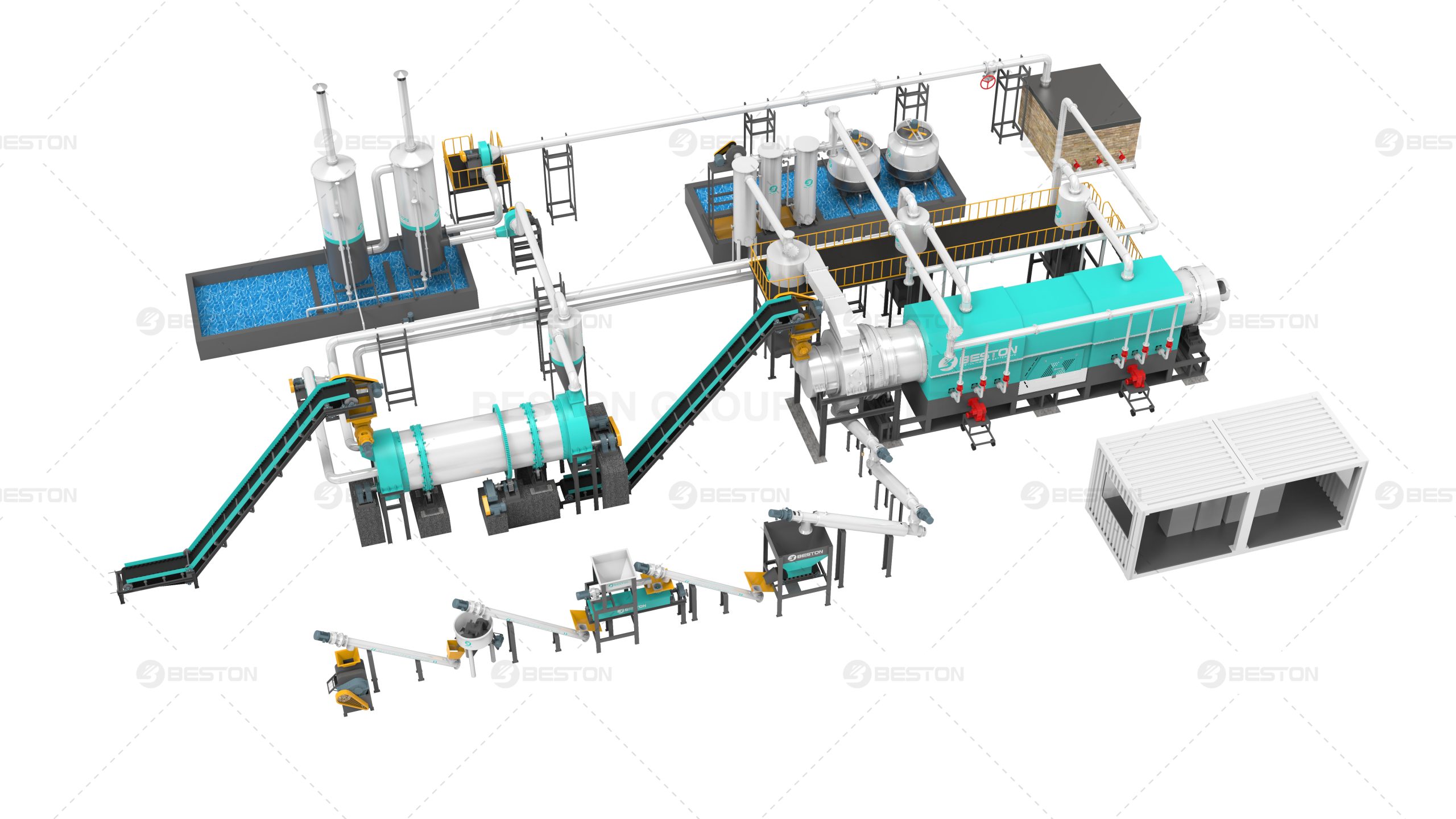

Beston Pyrolysis Plant Factory

Understanding Waste Pyrolysis:

Waste pyrolysis is a thermal decomposition process that transforms organic materials into valuable resources in the absence of oxygen. The process involves subjecting waste materials, such as plastics, rubber, and organic matter, to high temperatures, causing them to break down into gases, liquids, and char. The resulting products can be utilized for energy generation, chemical production, or even as raw materials for various industries.

The Promises of Waste Pyrolysis:

Resource Recovery:

Waste pyrolysis holds the promise of resource recovery from materials that would otherwise end up in landfills. By converting waste into useful products, it offers a potential avenue to reduce the strain on natural resources.

Energy Generation:

The production of syngas and bio-oil during waste tire pyrolysis equipment presents an opportunity for energy generation. These by-products can be harnessed to generate electricity or heat, contributing to a diversified energy portfolio.

Reduced Landfill Burden:

As landfills worldwide grapple with overcapacity, waste pyrolysis presents a potential solution by reducing the volume of waste sent to these sites. This could extend the lifespan of existing landfills and minimize the environmental impact of their expansion.

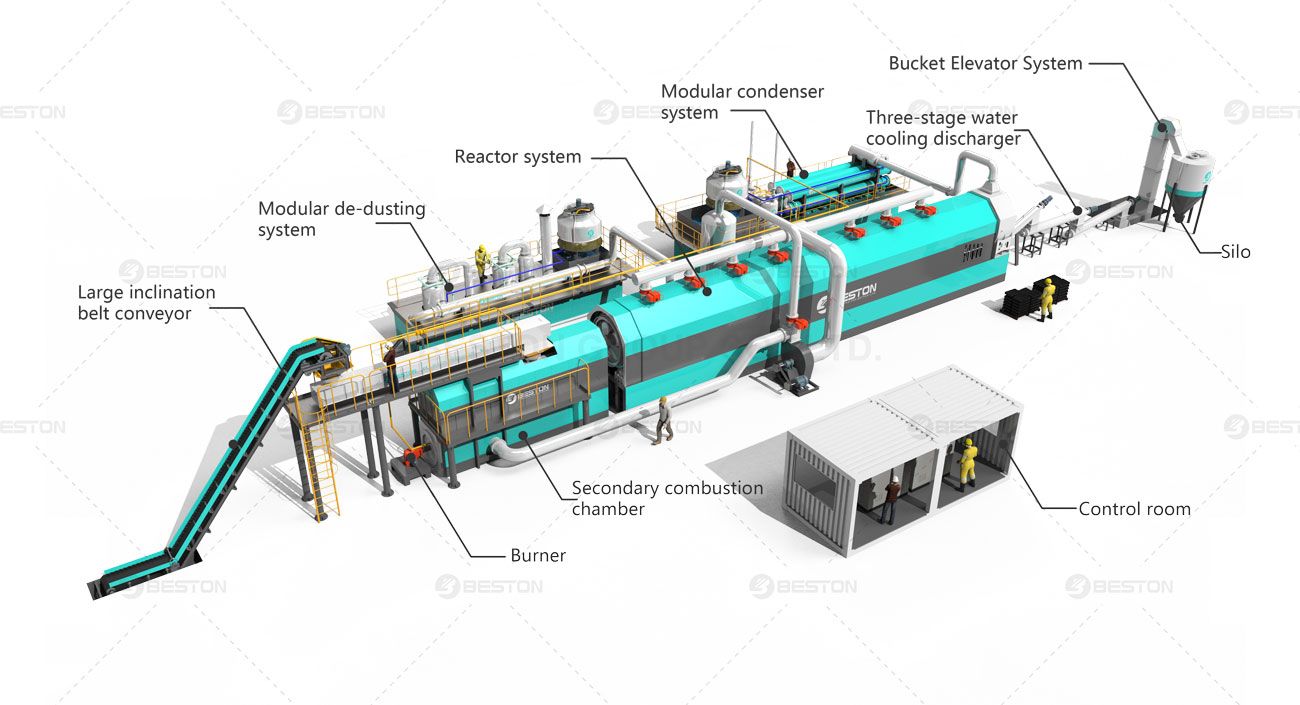

Tyre Pyrolysis Plant

Examining the Ecological Impact:

Emissions and Air Quality:

While waste pyrolysis avoids the direct combustion associated with traditional waste incineration, concerns arise regarding emissions during the pyrolysis process. Gases released, including carbon monoxide, volatile organic compounds (VOCs), and particulate matter, can contribute to air pollution if not properly managed.

Carbon Footprint:

The carbon footprint of waste pyrolysis depends on the feedstock used and the efficiency of the process. If not optimized, the release of carbon dioxide and other greenhouse gases may offset the potential environmental benefits, raising questions about its overall contribution to climate change mitigation.

Residue Management:

The char or solid residue left after pyrolysis requires careful consideration. If not managed appropriately, it could pose challenges similar to those associated with traditional incineration residues, including the potential leaching of harmful substances into soil and water.

Toxic Substance Concerns:

The transformation of various waste materials during plastic pyrolysis machine for sale can result in the release of potentially toxic substances. Understanding and mitigating these risks are crucial to ensure that the process does not inadvertently introduce harmful elements into the environment.

Regulatory Landscape and Best Practices:

Stringent Regulation:

Effective regulation is essential to govern the waste pyrolysis industry and mitigate potential environmental risks. Authorities must establish and enforce stringent emission standards, residue disposal guidelines, and monitoring protocols to ensure compliance with environmental norms.

Technological Innovations:

Ongoing research and development efforts are crucial to enhancing the efficiency and environmental performance of waste pyrolysis technologies. Innovations in reactor design, process optimization, and gas cleaning systems can contribute to minimizing the ecological footprint of pyrolysis operations.

Community Engagement:

Successful waste management strategies, including pyrolysis, require active participation and engagement from local communities. Public awareness campaigns and transparent communication about the benefits and risks of waste pyrolysis can foster a sense of responsibility and collaboration.

Conclusion:

Waste pyrolysis stands at the intersection of environmental challenges and potential solutions. While it offers a unique approach to waste management with the potential for resource recovery and energy generation, the ecological impact demands careful scrutiny. Striking a balance between harnessing the benefits of waste pyrolysis and addressing its environmental challenges requires a holistic approach involving technological advancements, robust regulations, and active community involvement. View some suitable models: https://www.bestongroup.com/es/.

As the world seeks sustainable alternatives for waste management, the journey through waste pyrolysis raises important questions about its ecological impact. Only through a comprehensive understanding of the process, coupled with responsible implementation and continuous innovation, can we hope to unlock the true potential of waste pyrolysis as a sustainable solution for a cleaner and healthier planet.