In the modern packaging industry, sustainability and efficiency have become paramount considerations. The shift from plastic to biodegradable materials has opened up significant investment opportunities, particularly in pulp egg tray production lines. Egg trays, a critical packaging material for the poultry industry, are increasingly being made from recycled paper pulp, offering both environmental and economic benefits. Investing in a pulp egg tray production line is not only a strategic business decision but also a move toward sustainability in manufacturing. Below, the various advantages of this investment are outlined in detail.

Cost-Effective and Sustainable Manufacturing

One of the primary reasons to invest in a paper pulp egg tray making machine is the cost-effectiveness of the manufacturing process. Paper pulp, the raw material used in egg tray production, is often derived from recycled paper products. This reduces raw material costs while also promoting a circular economy. The process itself is energy-efficient, especially when combined with advanced equipment such as an egg tray machine, which ensures high productivity and minimal waste.

The pulp molding process is designed to make full use of available resources. Waste pulp can be reused in the system, and water consumption is significantly reduced through closed-loop water management systems. Furthermore, the biodegradable nature of pulp products provides an eco-friendly alternative to plastic trays, which are gradually being phased out due to environmental concerns.

Increasing Demand for Biodegradable Packaging

The growing global focus on reducing plastic waste has led to an increased demand for biodegradable packaging materials. In many regions, regulations are being implemented to limit or ban the use of single-use plastics. This trend creates a robust market for egg trays made from pulp, as they provide an environmentally sound alternative to plastic trays without compromising on functionality.

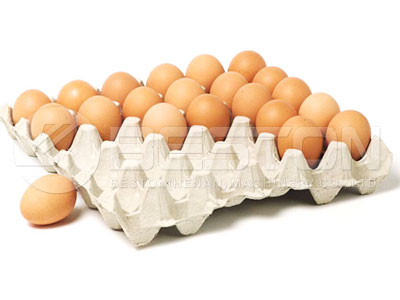

As businesses in the poultry industry, food packaging, and transportation sectors shift toward sustainable packaging options, investing in a pulp egg tray production line can position a company at the forefront of this transition. Egg trays made from pulp are not only biodegradable but also highly durable and shock-resistant, providing reliable protection for eggs during transport. This makes them an attractive choice for producers and retailers alike.

High Efficiency with the Egg Tray Machine

The efficiency of a pulp egg tray manufacturing machine is largely dependent on the equipment used, particularly the egg tray machine. Modern machines are designed to handle large volumes of pulp, molding it into trays at a rapid pace with minimal manual intervention. Automated systems reduce labor costs and increase output, making the production process both time and cost-efficient.

Moreover, egg tray machines are highly adaptable, allowing manufacturers to produce trays of varying sizes and shapes to meet different market requirements. The precision of these machines ensures uniformity and consistency in the final product, which is critical for packaging reliability. Additionally, most machines are designed with energy efficiency in mind, further reducing operating costs over time.

Technological Advancements in Drying Systems

Drying is a crucial step in the egg tray production process. Once the trays are molded from the pulp, they need to be dried to achieve the required strength and durability. Traditional drying methods can be time-consuming and inefficient, but advancements in drying technology have significantly improved this aspect of production. One such advancement is the introduction of multi-layer metal drying systems.

The multi-layer metal drying system is a highly efficient method that uses multiple layers of metal mesh conveyors to dry trays rapidly and evenly. This system reduces the space required for drying while ensuring uniform moisture removal from the trays. The heat is distributed evenly across the layers, and the trays pass through the system in a continuous flow, minimizing bottlenecks in the production process.

By incorporating a multi-layer metal drying system, fully automatic egg tray machine can significantly increase production capacity while reducing energy consumption. The system’s compact design also means that more trays can be dried in a smaller space, making it an ideal solution for high-volume production lines.

Flexibility and Scalability

Investing in a pulp egg tray production line offers significant flexibility and scalability. Manufacturers can easily adjust production volumes based on market demand, ensuring that they are not locked into a fixed capacity. This flexibility allows businesses to respond quickly to changes in market conditions, whether they need to ramp up production to meet increased demand or scale back during slower periods.

Furthermore, egg tray production lines are highly customizable. Businesses can integrate additional machinery or upgrade existing equipment, such as adding an automatic stacking system or upgrading to a more advanced egg tray machine. This scalability ensures that the production line can grow with the business, accommodating expansion without requiring a complete overhaul of the existing system.

Lower Operating Costs and Long-Term Profitability

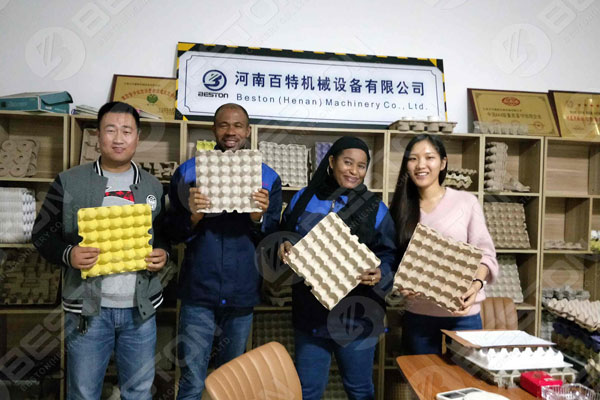

Although the initial investment in a pulp egg tray production line may seem significant, the long-term cost savings and profitability far outweigh the upfront expenses. The automation of the production process, combined with the use of energy-efficient systems such as multi-layer metal drying, reduces operating costs over time. Labor costs are minimized due to the high level of automation, while the use of recycled materials lowers raw material expenses. For more information on project investment, please contact Beston Group China.

In addition to cost savings, the growing market demand for biodegradable packaging ensures a steady revenue stream for businesses that invest in pulp egg tray production lines. As more industries prioritize sustainability, the demand for pulp trays will continue to rise, driving profitability for manufacturers who are well-positioned in the market.

Conclusion

Investing in a pulp egg tray production line is a sound business decision for companies looking to capitalize on the growing demand for sustainable packaging solutions. The combination of cost-effective manufacturing, high-efficiency egg tray machines, and advanced drying technologies like multi-layer metal drying makes this investment highly attractive. In addition to financial benefits, businesses can enhance their environmental credentials, comply with regulatory requirements, and future-proof their operations against shifts in market demand. As the packaging industry moves toward greater sustainability, pulp egg tray production lines represent a profitable and environmentally responsible investment for the future.