Have you ever asked yourself where all the waste tyres go? Did you know that what you consider scrap tyre has some economic value and can be disposed in a better way without degrading the environment? Today, with the advancing technology and increasing number of vehicles each day, companies have come up with better and effective tyre disposal methods. Other than burning, burying or leaving the tyres lying on the ground, a pyrolysis machine is used to do the thermo-chemical decomposition process known as pyrolysis. If you are willing to change the way you dispose your old tyres, this article highlights some of the things you should consider when shopping for waste tire recycling machine. Besides the cost, there are several other factors to take into account when buying this machine. A good machine should not only be efficient but also cost effective. An efficient pyrolsis machine recovers 100% of recycling thus bringing back to use what would otherwise be regarded as waste. The product of recycling is always used to rebuild other bi-products.

Properties of a good waste tyre recycling pyrolysis machine

Before deciding on the best machine to buy for your recycling work, seek as much information as possible about the manufacturer. A good machine should be eco-friendly, easy to operate, durable, of high performance, low maintenance cost, technologically advanced and manufactured using flawless technology. Also important to consider are the maintenance fee, electric charge, the size, level of automation and so on. Above all, a waste tyre pyrolysis plant cost should be reasonable, not very cheap but not very expensive. One of the most reliable cost cutting measures is choosing a machine that is fully automated. The semi-automatic may be cheaper but expensive in the long run considering that you will have to incur other expenses paying laborers.

What to look for in a good supplier

A good supplier should not only supply the machine but also install or give explicit directions on installation. You should also deal with a supplier who can provide a customized machine in case you need one. Also not that the performance of the machine matters a lot, a multi-purpose machine will work on waste trye, rubber, plastic waste, and even medical waste.

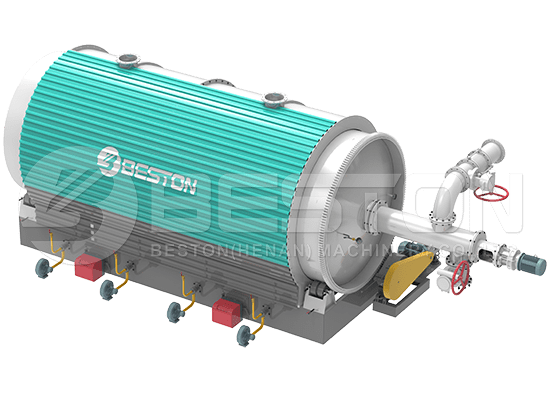

continuous waste tyre pyrolysis plant

Advantages of using a pyroylsis machine for tyre recycling

This tyre pyrolysis process leaves no waste or emission when used correctly

Some of the end products include oil, carbon blacks, steel, green products and high caloric combustible gas.

The end product can be use to produce power or oil type of liquid to be used as fuel, cleaning of diesel, and use in factories

The process is very clean and leaves no waste behind.