In the realm of sustainable fuel production, the charcoal briquette machine stands as a pivotal player, facilitating the transformation of raw materials into efficient energy sources. This article delves into the strategic implications of expanding a charcoal briquette machine production line, exploring the intricacies of operation, market dynamics, and environmental impact.

Understanding the Charcoal Briquette Machine

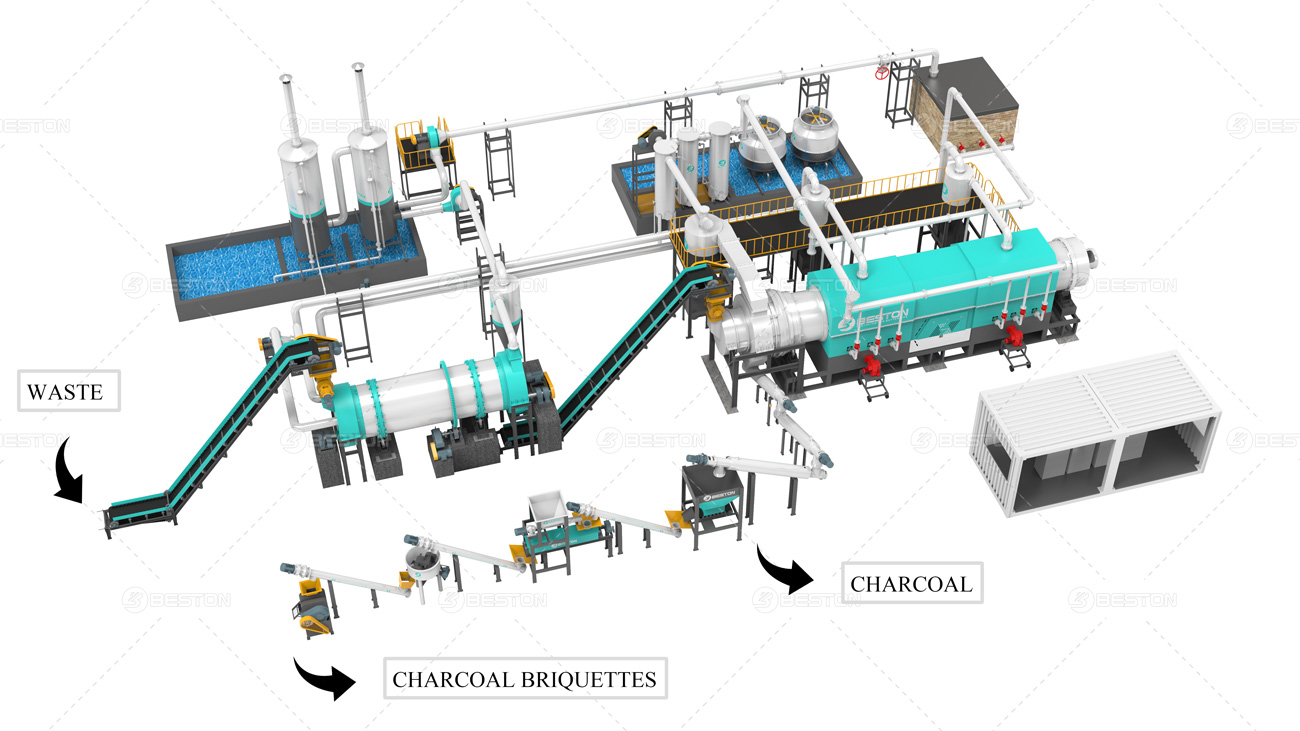

A charcoal briquette machine serves as the mechanical heart of charcoal production lines, where biomass materials such as sawdust, wood chips, or agricultural residues undergo transformation into compact, high-density briquettes. This process not only harnesses renewable resources effectively but also mitigates waste by converting it into a valuable energy commodity.

Key Components and Operation

At its core, a charcoal briquette machine integrates several critical components:

- Feeding system: Channels raw materials into the processing chamber.

- Compression chamber: Utilizes high pressure to compact biomass into briquettes.

- Heating system: Initiates the carbonization process, enhancing briquette quality.

- Control system: Regulates temperature, pressure, and production speed for optimal performance.

The operation begins with raw material feeding, where biomass is conveyed into the compression chamber. Here, under controlled pressure and temperature, the material undergoes compaction, forming dense briquettes suitable for various applications.

Market Insights and Opportunities

The global demand for sustainable energy solutions has propelled the charcoal maker machine market into prominence. Regions embracing renewable energy policies and eco-friendly practices exhibit substantial growth potential. Key sectors driving demand include:

- Household heating: Briquettes serve as economical alternatives to traditional fuels.

- Industrial applications: Used in metallurgical processes, heating furnaces, and more.

- Environmental initiatives: Support for biomass utilization in carbon-neutral projects.

Environmental Advantages

Embracing a charcoal briquette machine expansion plan aligns with environmental stewardship goals. Biomass briquettes offer significant advantages over conventional fuels:

- Carbon neutrality: Biomass combustion releases CO2, balanced by the carbon absorbed during plant growth.

- Waste reduction: Converts agricultural residues and forestry by-products into valuable resources.

- Energy efficiency: Higher calorific value and uniform combustion enhance overall energy yield.

Expansion Strategy and Implementation

Technical Considerations

Expanding a charcoal production machine involves meticulous planning and technical integration:

- Capacity scaling: Assessing current and projected demand to optimize production levels.

- Technology upgrades: Incorporating advanced automation and efficiency enhancements.

- Quality assurance: Implementing stringent standards for briquette consistency and performance.

Operational Efficiency

Streamlining operations enhances profitability and sustainability:

- Supply chain optimization: Securing biomass feedstock through sustainable sourcing practices.

- Energy management: Utilizing waste heat recovery systems to enhance operational efficiency.

- Maintenance protocols: Regular upkeep to ensure machinery longevity and minimize downtime.

Economic Viability

Investing in charcoal briquette machine expansion yields long-term economic benefits:

- Cost-effectiveness: Competitive pricing relative to fossil fuels amidst rising energy costs.

- Market diversification: Penetrating new sectors and geographic markets to broaden revenue streams.

- Government incentives: Capitalizing on subsidies and tax benefits promoting renewable energy adoption.

Conclusion

The evolution of charcoal briquette machine technology signifies a transformative shift towards sustainable energy solutions. By expanding production capabilities, stakeholders not only meet rising market demand but also contribute to environmental conservation efforts globally. This strategic endeavor underscores the critical role of innovation in advancing towards a greener future. If you have any questions about charcoal briquettes production, please contact Beston Group.

In summary, the journey towards a robust charcoal briquette machine expansion plan necessitates foresight, technical acumen, and a steadfast commitment to sustainability. As industries and communities embrace renewable energy alternatives, the charcoal briquette machine emerges as a cornerstone of this transformative movement, offering both economic prosperity and environmental stewardship.