If sorting through the different types of cranes available seems confusing to you, do not worry. It is a confusing subject because, while there are two basic styles of overhead cranes, they also come in a variety of configurations with a variety of options. This article will help explain the differences so that you can more easily distinguish the different types and more readily find the right one for your factory or facility.

Single Overhead Cranes

Single-beam and Double-beam Bridge Cranes

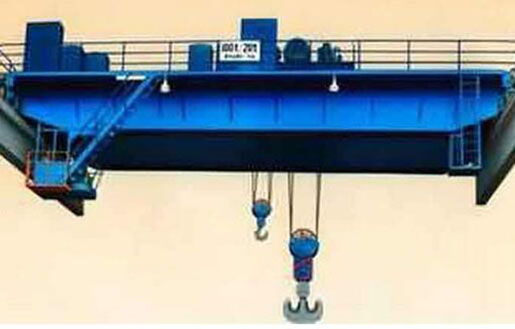

Firstly, these are the two major kinds of bridge cranes. They are sometimes called single-girder or double-girder cranes but they refer to the same types. Generally, a single overhead crane is more affordable to install and operate. A double-girder unit requires more installation only because it operates using two separate beams overhead which each need to be installed.

These two types of bridge cranes are made by many different manufacturers. These makers offer different options such as walkways, cabs, crane lights and magnetic cable reels or structural girders and hoists. While both types will carry loads, it is recommended that a single-girder is not used to transport high-production volumes of over 10 tons. Some may carry about 15 tons but anything over this is best left to a double-beam bridge crane.

Double-girders( doble viga birriel ) are ideal for high-volume weights over 15 tons and for spaces requiring more than a 65-foot span. Both will be offered at different speeds or they can also be purchased with multiple speed settings. Again, this option is something you would need to determine if it is important for your facility to operate at different speeds without holding up your production line.

The Best Overhead Crane

Specialty Bridge Cranes

There are also free-standing bridge cranes available. These are assembled on-site often without footers and the construction of the crane holds the bridge track within it. Think of them as steel beams arranged on all fours with tracks running through them.

This type is ideal for temporary job-site work or for buildings where the design does not facilitate installing any type of overhead bridge crane. If your facility can manage it, there is another option for a bridge crane and that is the underrunning crane.

The previous items discussed are called top-running cranes because, of course, they operate and carry items above ground or overhead. The under runners work by operating on tracks and beams installed low to the floor.

These underhung or under runner cranes maximize floor space so they are helpful in making any available space in your facility functional(tipo instalación funcional). This can be extremely economical and efficient, however, they do not hold heavyweights. The double-girder and single-girder overhead bridge cranes handle heavy weights nearly equally with some exceptions. The underhung machines are only for lightweight processes.

The Big Overhead Crane

Engineering and installing an underhung crane can be expensive because of the design factors involved in its operation. As if all these options were not enough to consider, there are also modular and process bridge cranes. One is for small facilities and the other, the process, is for heavy-duty processes.

contact with us: //www.weihuapuentegrua.cl/