In a world confronted with the challenges of climate change and environmental degradation, the need for sustainable and carbon-neutral solutions is paramount. Enter biochar, a versatile and eco-friendly carbon-rich material produced from biomass through the process of biochar pyrolysis equipment. In this in-depth exploration, we will discuss the concept of carbon-neutral biochar, how it is produced, its environmental benefits, and its potential applications in mitigating climate change.

Biochar From Biochar Machine

The Biochar Phenomenon

Biochar is a form of charcoal produced by the thermal decomposition of organic materials, primarily biomass, in a low-oxygen or oxygen-free environment through a process called pyrolysis. This method of biochar production results in a highly stable form of carbon that can be added to soil to enhance its fertility and simultaneously sequester carbon dioxide (CO2) from the atmosphere. This unique characteristic makes biochar a powerful tool in the fight against climate change and a promising solution for achieving carbon neutrality.

The Pyrolysis Process

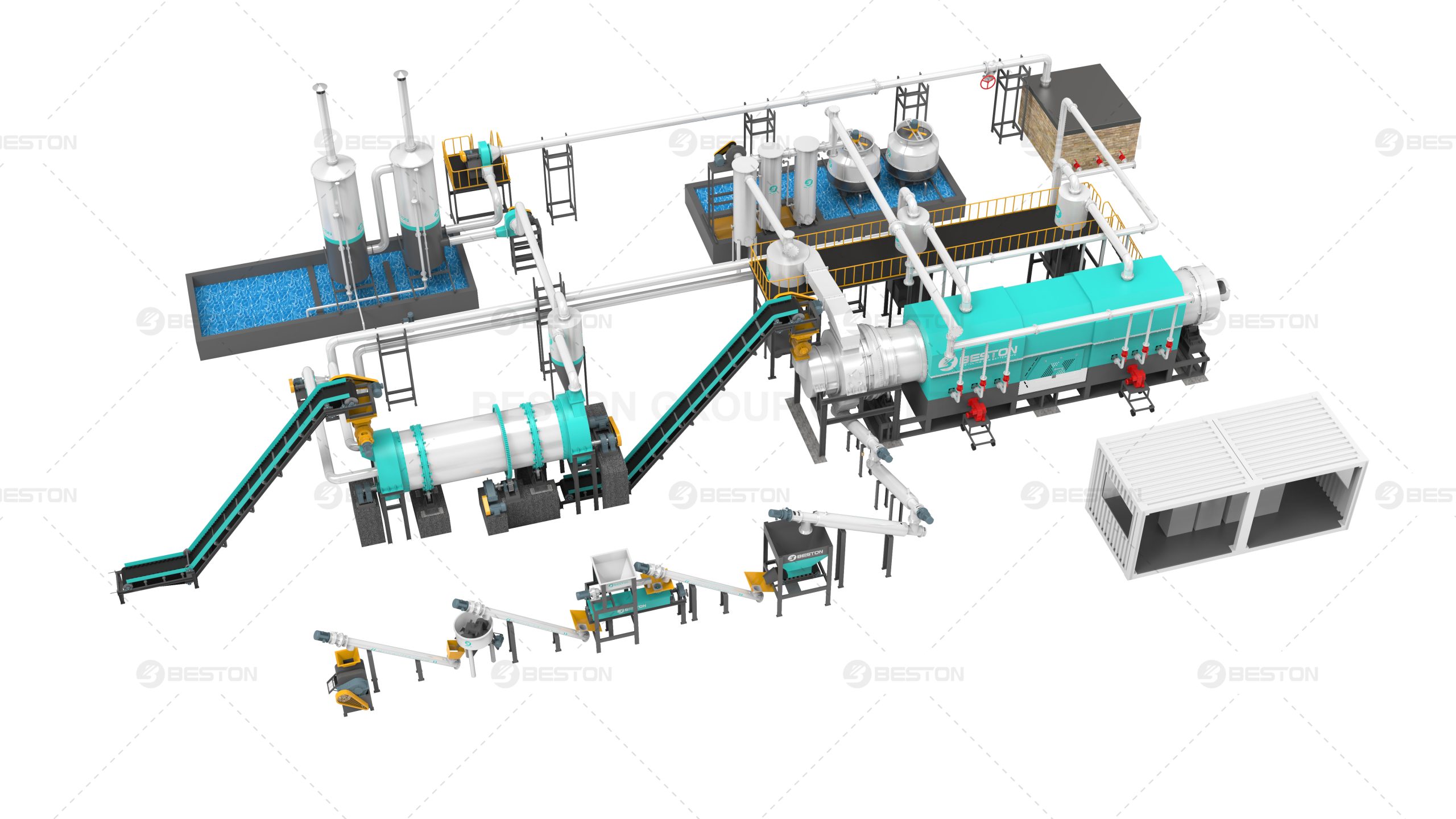

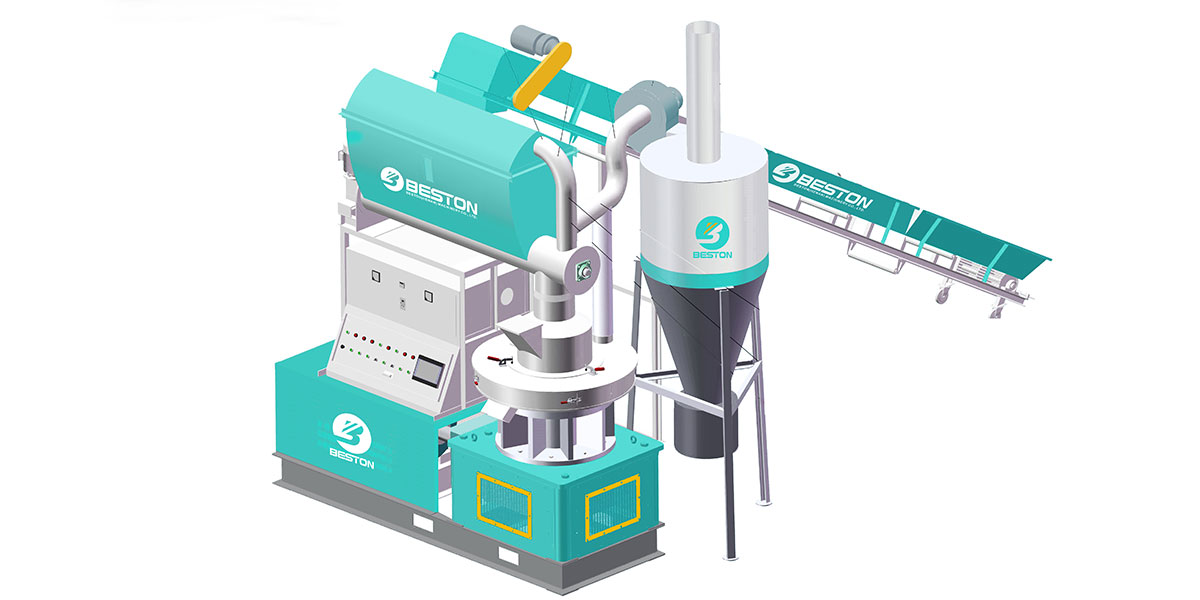

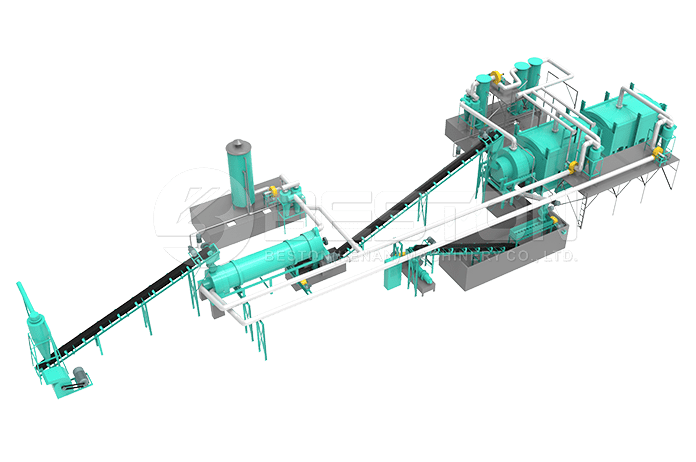

Before we delve deeper into the carbon-neutral aspects of biochar, let’s take a closer look at the biochar production units. Pyrolysis is a thermochemical conversion process that transforms organic materials into biochar, pyrolysis gas (syngas), and bio-oil. The key steps in the pyrolysis process include:

Feedstock Preparation: Biomass materials such as wood chips, agricultural residues, or other organic matter are collected and prepared for the pyrolysis process.

Heating and Gasification: The prepared biomass is heated to high temperatures (typically between 350-700°C) in an oxygen-limited environment, causing it to decompose into biochar, syngas, and bio-oil.

Cooling and Collection: The products of pyrolysis are then cooled and collected. Biochar is a solid, stable carbon product that remains in its solid state, while syngas and bio-oil can be used as renewable energy sources or further processed into valuable products.

Carbon-Neutral Biochar: The Key Characteristics

Carbon-neutral biochar refers to the concept of achieving a carbon balance within the process of producing and applying biochar. Here are the key characteristics that make biochar a carbon-neutral solution:

Carbon Sequestration: Biochar sequesters carbon in a stable form, preventing it from being released into the atmosphere as CO2. This sequestration can last for centuries, effectively locking away carbon.

Carbon Negative Potential: Biochar has the potential to be carbon negative, meaning it can offset more CO2 emissions than are generated during its production. When added to soil, biochar enhances carbon sequestration and promotes soil health.

Renewable Energy Production: Pyrolysis, the process used to create biochar, can be powered by renewable energy sources, minimizing the carbon footprint of the production process.

Carbon-Neutral Agriculture: When biochar is added to soil, it enhances its fertility and carbon storage capacity. Carbon-neutral agriculture is achieved when the carbon sequestration potential of biochar exceeds the carbon emissions associated with its production and transportation.

Environmental Benefits of Carbon-Neutral Biochar

Carbon-neutral biochar offers a wide range of environmental benefits, making it a compelling solution in the battle against climate change and environmental degradation:

Carbon Sequestration: Biochar has a high carbon sequestration potential, contributing to the reduction of atmospheric CO2 levels.

Enhanced Soil Fertility: When added to soil, biochar improves its nutrient and water retention capacity, making it more productive and resilient.

Reduced Greenhouse Gas Emissions: Carbon-neutral biochar can help reduce greenhouse gas emissions from agricultural practices, particularly when combined with sustainable farming techniques.

Reduced Waste Disposal: The production of biochar can utilize biomass waste materials, reducing the need for waste disposal and incineration, which release CO2 and other pollutants.

Improved Air Quality: The use of renewable energy sources for pyrolysis in biochar production reduces air pollution and carbon emissions associated with traditional energy sources.

Reduced Deforestation: Biochar can serve as a sustainable alternative to traditional charcoal production, helping to reduce deforestation and protect forests as vital carbon sinks. Jute stick is a suitable raw materials. View more information: https://bestonmachinery.com/charcoal-making-machine/jute-stick/.

Applications of Carbon-Neutral Biochar

Carbon-neutral biochar has a wide range of applications across various sectors, contributing to its environmental and sustainability benefits:

Agriculture: Adding biochar to agricultural soils enhances fertility and productivity, reducing the need for synthetic fertilizers and improving crop yields.

Carbon Farming: Carbon-neutral biochar can be integrated into carbon farming practices, where land managers receive financial incentives for carbon sequestration and emissions reductions.

Soil Remediation: Biochar can be used in soil remediation efforts to mitigate the impacts of contaminated or degraded soils.

Livestock Farming: Biochar can be used as a feed supplement for livestock to improve digestion and reduce methane emissions.

Water Filtration: Biochar can filter contaminants from water sources and improve water quality.

Energy Production: Biochar can be used as a renewable energy source when burned as a solid fuel or converted into syngas for electricity generation.

Construction Materials: Biochar can be integrated into construction materials, such as concrete and bricks, to reduce their carbon footprint.

Economic Considerations

The economic feasibility of carbon-neutral biochar production depends on several factors, including feedstock availability, technology selection, market dynamics, and government incentives. While the initial capital investment for pyrolysis equipment can be significant, the long-term environmental and agricultural benefits often outweigh the costs.

Government policies that promote carbon sequestration, sustainable agriculture, and renewable energy sources can further enhance the economic feasibility of carbon-neutral biochar production. Carbon credits and incentives for soil carbon sequestration can also provide revenue streams for producers and farmers.

Conclusion

Carbon-neutral biochar produced through pyrolysis offers a promising solution to the pressing challenges of climate change, soil degradation, and waste management. Its unique ability to sequester carbon while enhancing soil fertility and improving agricultural practices makes it a valuable tool in achieving carbon neutrality and a more sustainable future.

As technology advances and environmental awareness grows, carbon-neutral biochar is poised to play a significant role in mitigating climate change and promoting environmental sustainability. With the right incentives, policies, and investment, biochar can become a vital component of our efforts to combat climate change and build a more sustainable world.